Neoprene a Good Balance of Performance Compound Materials

Neoprene, a synthetic rubber material, offers exceptional flexibility and durability due to its unique molecular structure. It excels in applications requiring strength and adaptability, making it ideal for various industries. With outstanding resistance to oils, chemicals, heat, and weathering, neoprene maintains its shape and integrity even in harsh environments. Its ability to stretch and conform to different shapes, while withstanding extreme temperatures, reduces maintenance costs. Neoprene strikes a perfect balance between performance, making it a powerhouse material for demanding applications. Learn more about neoprene’s composition, properties, applications, and advantages for a deeper understanding of its versatility and benefits.

Key Points

- Neoprene offers exceptional flexibility and durability for various applications.

- It provides outstanding resistance to chemicals, oils, and harsh environmental conditions.

- The material maintains its shape and structural integrity even with stretching and bending.

- Neoprene is ideal for industries requiring strength, adaptability, and longevity.

- It is a cost-effective solution, reducing maintenance costs and frequency of replacements.

Neoprene Composition and Structure

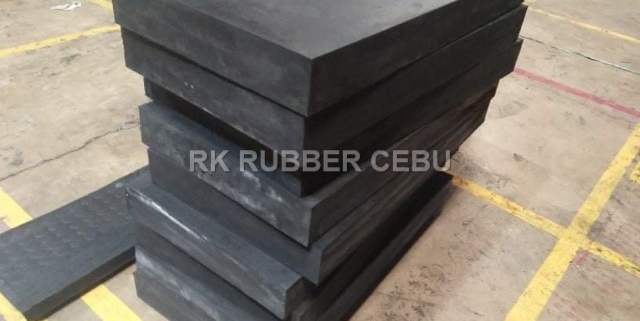

Neoprene, a synthetic rubber material, is composed of polychloroprene, a polymer known for its structural flexibility and resistance to various environmental factors. The unique molecular structure of neoprene provides it with exceptional flexibility, allowing it to stretch without losing its shape or structural integrity. This inherent neoprene flexibility makes it an ideal material for a wide range of applications, from wetsuits to industrial gaskets.

Moreover, neoprene’s durability is a key factor in its widespread use across industries. The material exhibits excellent resistance to oils, chemicals, heat, and weathering, making it a reliable choice for demanding environments where other materials may fail. Additionally, neoprene’s ability to maintain its properties over a wide temperature range further enhances its durability and longevity.

Key Properties of Neoprene

The exceptional flexibility and durability of neoprene stem from a combination of unique molecular properties that make it a versatile and reliable material for various applications. Neoprene, a synthetic rubber material, exhibits outstanding durability due to its resistance to degradation from oils, chemicals, and sunlight exposure. This durability makes neoprene a preferred choice in industries where harsh conditions are prevalent. Additionally, neoprene’s flexibility is a key property that sets it apart from other materials. Its ability to stretch and bend without losing shape or structural integrity makes it ideal for applications requiring both strength and adaptability. Whether used in wetsuits for diving, automotive hoses, or gaskets in machinery, neoprene’s flexibility ensures it can conform to different shapes and maintain its performance over time. The combination of durability and flexibility in neoprene makes it a powerhouse material in a wide range of demanding environments.

Applications of Neoprene

An array of industries benefit from the versatile properties of neoprene, utilizing this synthetic rubber material for a wide range of applications requiring durability and flexibility. Neoprene’s unique characteristics make it a valuable material in various sectors, including:

- Neoprene in fashion: The fashion industry incorporates neoprene in designing wetsuits, gloves, shoes, and other apparel items due to its water-resistant and stretchable nature.

- Neoprene in sports: Sports equipment such as wetsuits, knee braces, and athletic gear often utilize neoprene for its ability to provide insulation, cushioning, and support during physical activities.

- Automotive applications: Neoprene gaskets, hoses, and seals are essential components in vehicles, offering resistance to oils, chemicals, and extreme temperatures.

- Medical industry: Neoprene is used in orthopedic braces, prosthetic limbs, and medical gloves due to its hypoallergenic properties and resistance to degradation.

- Industrial uses: Neoprene’s oil and chemical resistance make it ideal for conveyor belts, hoses, and protective gear in industrial settings where durability is paramount.

Advantages of Neoprene

With exceptional resistance to various chemicals, oils, and extreme temperatures, neoprene stands out as a versatile and durable material in a wide range of industries. Its durability is a key advantage, making it highly resistant to degradation from exposure to harsh substances, ensuring longevity and reliability in demanding environments. Neoprene’s flexibility is another notable benefit, allowing it to conform to different shapes and maintain its properties over a wide temperature range. This flexibility not only enhances its adaptability to diverse applications but also contributes to its ease of handling during manufacturing processes.

Moreover, neoprene’s exceptional durability extends its lifespan, reducing the frequency of replacements and maintenance costs, providing a cost-effective solution in the long run. Its robust nature also makes it suitable for challenging conditions where other materials may fail, showcasing its superior performance and reliability. To conclude, the advantages of neoprene, including durability and flexibility, position it as a top choice for industries requiring resilient and adaptable materials.

Frequently Asked Questions

Can Neoprene Be Recycled or Is It Biodegradable?

Recycling options for neoprene are available, as the material can be repurposed into new products. However, neoprene is not biodegradable, posing challenges for environmentally friendly disposal methods. Proper recycling procedures should be followed to minimize waste impact.

Are There Any Potential Health Risks Associated With Neoprene?

Potential allergies and skin irritation may arise from neoprene exposure due to chemical sensitivities. Research suggests these risks may impact some individuals. It is essential to take into account personal health factors when working with this material.

How Does Neoprene Perform in Extreme Temperature Conditions?

Neoprene exhibits exceptional temperature resistance, maintaining its performance in both hot and cold extremes. Its insulation properties make it a reliable choice for applications requiring stability across a wide range of temperatures.

What Are the Limitations of Neoprene in Terms of Use?

When it comes to use, neoprene shows limitations in durability over extended periods of heavy mechanical stress. Regular maintenance, including cleaning and proper storage, is essential to extend its lifespan and maintain peak performance in various applications.

Is Neoprene Affected by UV Exposure or Sunlight?

Neoprene’s durability and UV resistance make it suitable for outdoor applications where exposure to sunlight is a concern. Its ability to withstand UV rays enhances its longevity, making it a reliable choice for various outdoor settings.

Conclusion

Neoprene is a versatile compound material with a unique composition and structure that lends itself well to a variety of applications. Its key properties, including resistance to oil, heat, and weathering, make it a popular choice in industries such as automotive, marine, and sporting goods. The advantages of neoprene, such as its durability and flexibility, make it a reliable and efficient material for various uses.